21

FEBHow Efficiency Indicators on the Logistic System are Connected to the Balanced Scorecard System

CHAPTERS:

1.GENERALLY

2.THE BALANCED SCORECARD SYSTEM

3.THE STRATEGY MAP

4.SPECIAL INDICES FOR THE LOGISTICS SYSTEM

5.ACTIONS FOR IMPROVEMENT

1. GENERALLY

It is well known that the efficiency improvement in the Supply Chain constitutes an important challenge to improve the profitability, to increase the sales volume and to upgrade the provided service to the customer. All the above apply to all enterprises. Experience however shows that despite the important improvements that a lot of enterprises have realized in this sector moreover, a lot of enterprises continue to provide a very low level service, while maintaining an absurdly high cost of reserves, of distribution of material products and benefit of remaining services in other words maintaining a very high operational cost for the supply chain and giving bad quality service. There are lots of factors responsible for that condition, yet it is proven that all enterprises can improve at a remarkable pace, as long as they follow the steps described below:

-

Making a record of each activity and preparing a flow chart with these activities

-

Determining critical indicators that affect the performance of these activities

-

Determination of methods measuring the indicators.

-

Establishment of objectives for these indicators

-

Measuring performance in the present situation

-

Designing of an action plan for cases where the measurements do not correspond to the objectives

-

Reviewing and continuously improving the results

The importance of establishing indicators is of great value since each improvement can be achieved only through measurement of the corresponding indicators based on the out of sight, out of mind principle.

2. THE BALANCED SCORECARD SYSTEM

The connection of these indicators with the Business plan (Vision - Strategic Objectives) should be direct, since the Business Plan should mobilise all forces of the enterprise. The most complete System that has been developed at a worldwide level up to present is the Norton and Kaplan System, known as Balanced Scorecard, that aligns the forecast objectives to the four basic perspectives of the enterprise, and connects the relative indicators with the strategic objectives of the enterprise.

The four basic perspectives relate to the:

-

Financial Sector

-

Customer Satisfaction

-

Process Performance

-

Human Recourses and Infrastructures

According to this System the Indicators project the Corporate Logic and promote the methodology that produces long-term results in a cohesive way through the above areas of corporate action by materiallising all necessary the actions. So, through these Indicators the objectives of the Plan are transformed into daily practices in the framework of the enterprise. This logic appears descriptively in the following example:

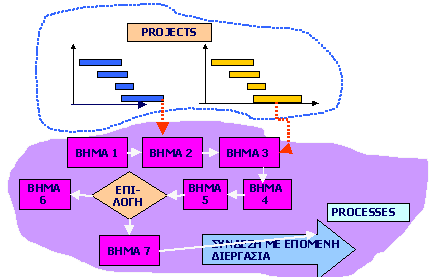

Fig. 1: Example of Connecting Logistics Indicators with the Balanced Scorecard System

As shown in the above diagram for each strategic objective Indicators are formed, which cover the above four perspectives. The relevance of these Indicators with the strategic objectives is a cause and effect relationship, meaning that when the Indicator objectives are achieved the strategic objectives will also be achieved. Depending on the results, review and possible amendment of the Indicators or the specific objectives will be made. In order to achieve these objectives for the improvement of Processes, a series of planned actions will be required. The specific Action Plans appear in the diagram above. Of course, each time, the results of the Action Plans are evaluated.

In addition, for each critical process the appropriate financial support is necessary. In this way, an efficient and effective Budget is prepared. Through this approach a Budget is directly aligned with the business strategy.

As a result, the Balanced Scorecard System has the dual target:

-

On the one hand, to produce an organized “diffusion” of indicators to all action levels of the Enterprise, tracking the cause and effect relationship of the various actions in the four perspectives areas, so that the focus on each action level to “sweep along” all subordinate levels

-

On the other hand, to secure a "balanced" target, that will deter the achievement of high level objectives in one area of the company, against the expected results in other areas

-

This System protects us from situations where, for example, a target to increase the market share of an area by 3%, is realized by hiring expensive and high cost salesmen. By this action, however, another target area to contain salaries at a certain level may collapse.

3. THE STRATEGY MAP

The balanced distribution of indicators and the correct reporting system is achieved, to a big extent, from the possibility to impress accurately the Investment Plan for an effective supply chain management under the form of a Strategy Map.

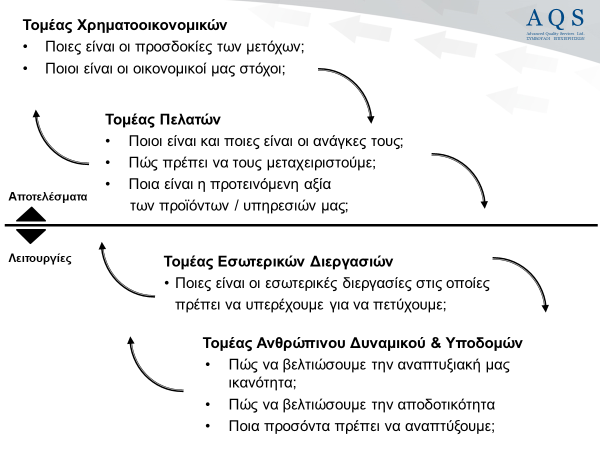

The Strategy Map allows us to have a concise and holistic picture of the critical strategic actions for each of the four perspectives

This generalized approach provides answers to the following questions:

For an effective application of the Balanced Scorecard in the area of Logistics we should take into consideration the relevant special aspects of the supply chain management (SCM), as well as, the appropriate strategic targets and performance indicators. According to various studies, companies that assign the supply chain management to the Business Strategy, aim at achieving the following targets :

25-50% reduction of the total supply chain costs

25-60% reduction of inventory-holding

25-80% increase in demand forecast

30-50% improvement of the customer order-fulfilment cycle time

An indicative approach of the Strategy Map, for a better understanding of its practical implication, is presented in the figure that follows :

STRATEGY MAP

The result is an integrated evaluation system, structured according to the pioneering methodology of the Balanced Scorecard, which is applied efficiently in the special needs of Logistics.

As a result, the strategy map offers us the possibility to attend to the materialization course of business objectives. So, for every Strategic Objective Key Performance indicators are developed that cover the above mentioned four perspectives. The relationship of these indicators with the strategic objectives is between cause and effect, meaning that when the objectives of each indicator are achieved the strategic objectives also will be achieved. In addition, this relationship contributes to determining the causes for a low level performance (under the targeted level), so that decisions could be taken for immediate corrective actions.

4. SPECIAL INDICES FOR THE LOGISTICS SYSTEM

The following indices could be included in the Balanced Scorecard System for Logistics:

ΤΟΜΕΑΣ (PERSPECTIVE) |

ΓΕΝΙΚΟΙ ΔΕΙΚΤΕΣ (STRATEGIC LEVEL) |

ΕΙΔΙΚΟΙ ΔΕΙΚΤΕΣ (OPERATIONAL LEVEL) |

Ικανοποίηση Πελάτη |

- Συνολική ικανοποίηση πελάτη- Παράπονα πελατών- Βελτίωση εξυπηρέτησης πελάτη (Customer Service Level) |

- Ποσοστό τέλειων παραγγελιών - Ποσοστό έγκαιρων παραδόσεων (ανά κατηγορία προϊόντων βάσει της ABC ανάλυσης) - Ποσοστό back orders - Αριθμός παραπόνων πελατών - Χρόνος ανταπόκρισης σε αίτημα - παράπονο πελάτη - Αξιοπιστία προϊόντος - Σχέση τιμή / ποιότητα - Διαθεσιμότητα προϊόντος - Δημιουργία partnership - Αξιοπιστία στις συναλλαγές |

Εσωτερικές Διεργασίες |

- Κόστος αποθήκευσης- Κόστος διανομής- Ακρίβεια αποθέματος- Χρόνος cash to cash (Χρόνος μεταξύ αγοράς υλικών και είσπραξης χρημάτων από τα προϊόντα που παρήχθησαν)- Ποσοστό κόστους μεταφορών προς κόστος πωλήσεων- Ποσοστό κόστους μεταφορικών προς κόστος διανομής |

- Χρόνος αποστολής προσφοράς στον πελάτη - Κύκλος παραγγελίας πελάτη - Ποσοστό σωστά συμπληρωμένων τιμολογίων - Χρόνος ετοιμασίας παραγγελιών ανά γραμμή - Μονάδες που παρελήφθησαν στη μονάδα χρόνου - Σφάλμα πρόβλεψης ζήτησης - Ποσοστό αξιοποίησης δυναμικότητας οχημάτων - Χρόνος παραμονής εξοπλισμού εκτός λειτουργίας - Απόδοση εργαζομένων στην ετοιμασία παραγγελιών - Χρόνος παραμονής αποθεμάτων στην αποθήκη (ανά κωδικό) - Ποσοστό χρησιμοποιούμενου χώρου αποθήκης - Ποσοστό επιστρεφόμενων ειδών από πελάτες - Αριθμός «γυρισμάτων» αποθεμάτων - Μείωση του κόστους επεξεργασίας παραγγελίας - Εκτελούμενες παραγγελίες ανά 24ωρο - Μείωση κόστους υλικών - Μείωση ποσοστού ασυμφωνίας λογιστικού και πραγματικού είδους - αποθέματος |

As the above table indicates, indices are separated into General and Special. This is an important separation because it allows us to apply the cause and effect relation, which means that when the targets of the Indices are achieved the strategic targets will also be achieved. This way, the General Indices are directly connected with the strategic indices (strategic level), while the Special Indices constitute the checking points for the performance of business operations (operational level). In other words, the Special Indices constitute the critical factors where we should intervene, when this becomes necessary, i.e., to secure the achievement of the strategic targets.

5. ACTIONS FOR IMPROVEMENT

The above indices relate to processes. Namely, to reduce the forecast error in the demand forecast we should re-examine the steps to be followed, and most probably the establishment of a Structured System of Inventory Management might be necessary. By the way, such an action could reduce the inventory management cost to a level of 30 %. This result derives not from international practice only, but also from our own experience, in the case of our customers, where we witnessed inventory reductions exceeding the 30% level.

We could exhibit the small or big projects that are required for the improvement of processes that relate to indices with the figure that follows: